Sharp Knife Verified

Quantifying Sharpness III, Quality Control Video!

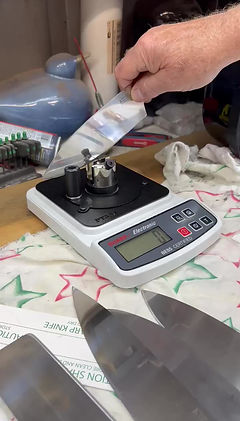

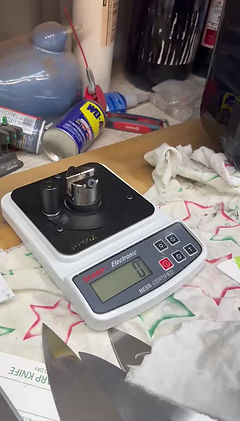

Scroll down for three short videos of the Edge On Up Sharpness tester in use. To continuously improve product quality, we have to measure where we're at today. When I got the Fixed angle sharpening systems I now have, the quality of sharpened edges at Keith Nix Knives jumped dramatically. Now that I can directly measure the sharpness of those edges, I expect to squeeze every last drop of keenness out of my sharpening protocols.

Quality Control and Continuous Improvement-

If you want a sharp knife, you must know how to get there and understand WHEN you are there!

There is no quality without quality control; if there is, it is BLIND LUCK. As a knifemaker, I must control time and temperature in all heat-treating processes as I make your knife. Quality management is controlling manufacturing processes! When I create your fine wood handle, I have to maintain flatness and parallelism early in the process to ensure the handle fits the tang without gaps. The pin holes must be drilled perpendicular to the handle's flats and reamed to a very tight tolerance. We measure and control many variable temperatures, dimensions, material conditions, and surface finishes to ensure the best custom knives we can make, with an eye to continuous improvement. So I was overjoyed to find the Edge on Up sharpness tester and the BESS Scale of sharpness. Now we can measure sharpness because sharpness is necessary for a knife.

Here are three videos Sarah shot for me on 7/22/2022. The top one of her beautiful but dull Keith Nix Knives petite chef's knife shows it cutting the certified test media, requiring nearly 550 grams of force, or 550 on the BESS scale (Brubacher Edge Sharpness Scale). This is the starting point and shows how dull the knife had become. Quality Assurance, Quality Control, and Sharper Edges begin by establishing a baseline to be sure our products meet customer expectations!

The second video shows the knife after sharpening with 80 to 2000-grit bonded diamond stones and finishing with a 3000-grit ceramic, all at 16.5 degrees per side. This part of the test was conducted BEFORE stropping. Force to cut was reduced to 198 grams or 198 BESS scale. This is precisely the routine I now use on every knife I sharpen. Sharp, but NOT sharp enough. This is Quality Control in action.

Video three shows the same knife with no further sharpening on the stones, but after stropping on a hard-backed denim strop loaded with Flitz chrome polish, and then a smooth leather strop loaded with 1-micron diamond paste. The knife received only THREE strokes per side on each of the two strops. The stropping took the knife to 156 BESS, right in the middle of the sweet spot I'm looking for. This is Quality Assurance!

Findings-

This little test reveals a couple of surprises.

1- Knives sharpened to high grit finishes at FIXED angles and deburred well with each stone, need very little stropping, but they do need stropping to reach maximum sharpness.

2- To get the most from your sharpened edges, light stropping as a "deburr and polish" finishing step is a necessity.

3- Sarah didn't think her knife was particularly dull. It was awful.

4- OVER STROPPING is a very real phenomenon, at least for me. I will be KEENLY aware of that in the future.

5- The Edge on Up Sharpness Tester has a place in our shop going forward. We cannot improve or control what we don't measure! Now we can rest assured you're getting the SHARPEST KNIFE we can offer! Sharp Knife Verified!

The quality management process should make evidence-based decisions and work toward incremental improvements in every area of a business. Customer satisfaction is very important, but we believe making the best knives we are capable of making is our highest goal! Your complete satisfaction and long-term patronage is our NUMBER ONE goal!

To Make an Appointment for Knife Sharpening Near you, Click Here!

More FREE Learning:

Quantifying Sharpness I

Quantifying Sharpness II

Knife Safety Tips

Order Your Custom Knife From the Keith Nix Knives Shop Now!

Sign Up For The Keith Nix Knives Newsletter! Click HERE!

keithnixknives@gmail.com

828-337-7836

Thanks for reading,

Keith

Keith Nix Knives