FREE Learning- Why Cryo Treat Knives?

- Keith Nix

- Jul 1, 2022

- 4 min read

Updated: May 23, 2023

Why Use Liquid Nitrogen? What Is Liquid Nitrogen? What Does It Do? How Do You Know It Does That? Will LN2 Fix a Bad Heat Treatment?

People ask questions! And we're going to try and provide some answers today about one of the most misunderstood parts of heat treating knives- the cryogenic quench! WHAT IS LIQUID NITROGEN? The air we breathe is 78% gaseous nitrogen. It is all around us as you read this. So there's plenty of this element, but we need it to be liquid, and we need it in a container! This involves a process called "air liquification", which compresses and chills air or gaseous elements to the point where its constituent components separate and liquify. (carbon dioxide solidifies at -120F, nitrogen liquefies at -320F, oxygen at -297F, hydrogen at -423F). Knowing that, the liquifier can collect each liquified gas at a specific temperature, pretty much in its pure state. Much like a liquor still purifies and collects alcohol, except the temperatures are reversed! Then all that's necessary is to keep it cold, and pump it into my dewar. The vacuum insulated dewar I own insulates so well I only fill it about twice a year! Now remember, LN2 boils at -320F, so I think that's amazing!

Why Use Liquid Nitrogen?- When a knife steel is heated to a certain point it changes to a softer, nonmagnetic phase called austenite. That "certain point" is modified by the carbon and other alloying content of the steel. Then as we quench the blade back to room temperature, it will pass a point called Ms "martensite start" , where the austenite begins to convert to the harder, stronger martensite(we want this conversion!). As the steel continues to cool is passes a point called Mf "martensite finish". Now, due to carbon content and other alloying, that Mf temperature can be below room temperature, below freezing, and sometimes even below dry ice temp.(dry ice, or solid CO2 is at least -120F). This can leave a percentage of the matrix as "retained austenite", which isn't a good thing for a variety of reasons.

It is critical that the knife go straight from room temp to LN2. A delay of even a few minutes, or the sometimes recommended "snap temper" before LN2 offers an opportunity for the retained austenite to stabilize. Don't even check hardness, get your blade in the LN2 now!

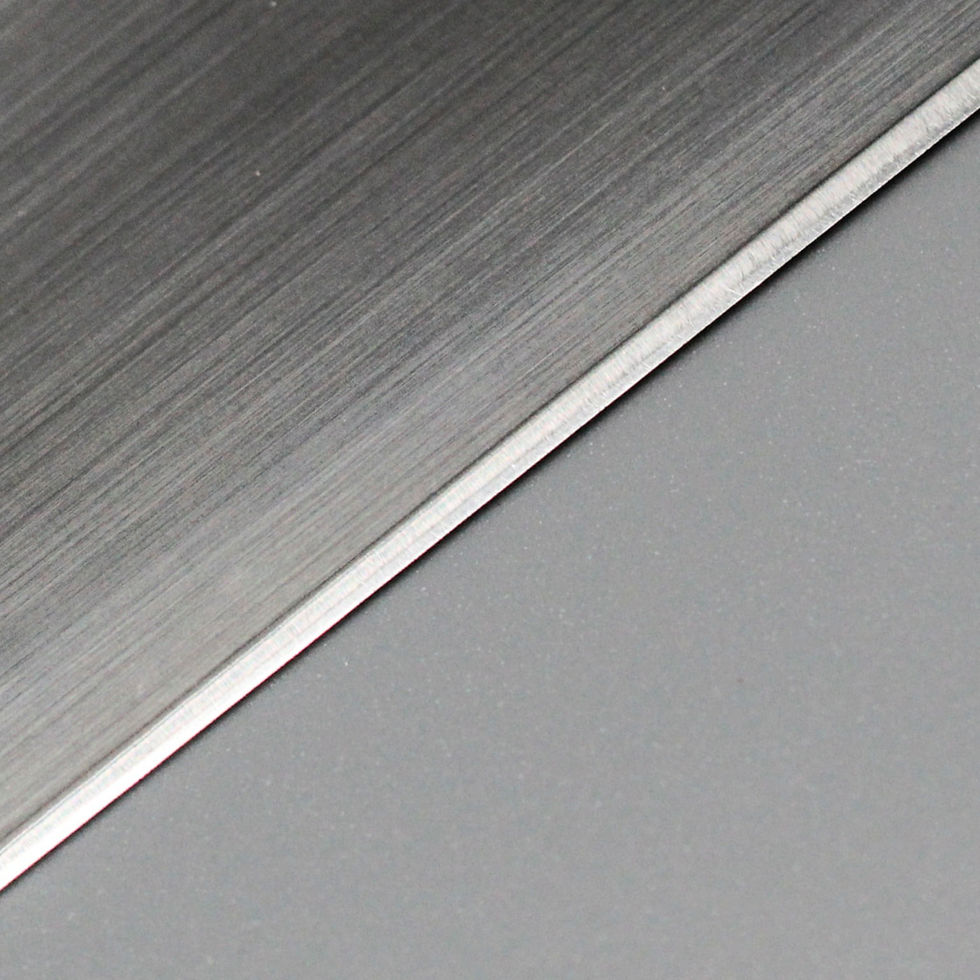

What Does LN2 Do?- This is the reason LN2 is the choice for cryo treating to insure Mf. It is cold enough to facilitate the conversion of retained austenite(RA) to hard martensite. There are reasons we want to convert this RA as soon as possible. Here are a few: 1) Retained Austenite makes the matrix of the steel softer. At levels around 20% or above, RA negatively affects the bulk hardness of the blade, hindering performance and sharpenability. 2) Under certain stresses, RA can spontaneously convert to untempered martensite. There is a valid reason we temper our knives after hardening. Untempered martensite is extremely brittle and prone to fracture. It has very low toughness. It is prone to chipping. It creates crack initiation points and stress risers. BAD JUJU! 3) RA negatively affects edge retention and sharpenability. Softer steels are harder to properly sharpen than harder ones. Soft steel doesn't want to take a crisp edge, doesn't want to let go of the burr or foil edge when stropping. And then the softer high RA knife gets dull many times faster. How Do You Know LN2 Does That?- There are a number of ways to accurately measure the effects of LN2 on steel.

1) Rockwell Hardness Tester. Running sample coupons before and after LN2, before and after LN2 AND tempering, and at different temperatures, and checking the hardness of each one is a knifemaker's way of verifying our processes are giving the results we expect! 2) Magnetic Resonance Since RA is nonmagnetic, a very accurate measurement can be made of how much RA is in a given piece of steel. While I do not have the means to conduct this test, there is plenty of research available to verify the theory.

To the left here is a chart created by Dr Larrin Thomas, showing the effects of austenitizing temperature (hardening temp) and room temp quench vs home freezer vs LN2. It is easy to see that LN2 treated samples are 3.5 Rc points harder compared to room temperature, and 2.5 points harder compared to a home freezer treatment. That's quite a difference, and exactly why I use LN2 treatment on all knives at Keith Nix Knives.

Will LN2 Fix A Bad Heat Treatment? - No, LN2 will NOT fix a bad heat treatment. If a custom knife is austenitized at too low a temp, it won't fully harden. LN2 cannot fix that. If the knife is austenitized at too high a temp, awful things can happen like explosive grain growth, too much carbon in solution, and so much excess RA even LN2 can't save the piece. So LN2 isn't a "fix" for anything. It is a logical continuation of a proper heat treatment, that can enhance desirable properties of the blade. Learn more about heat treating HERE! My desire is to make the very best knives I am capable of making. To get the geometry right for the knife and the tasks it will perform. The best support for that geometry is a hard steel matrix that supports the carbide structure of the steel, resists edge rolling and chipping, and sharpens easily. LN2 helps steels achieve all those properties.

(Special Thanks to Dr Larrin Thomas of Knife Steel Nerds for his seemingly unending research and generous sharing of his findings with the knife making community.)

More FREE Learning:

Order Your Custom Knife from Keith Nix Knives Shop Now! keithnixknives@gmail.com

828-337-7836 Thanks for reading, Keith Keith Nix Knives

So where does the liden frost effect come into play? wouldnt the knife create a layer of "steam" thatd prevent it from getting an even temper?

very informative blog . thanks for sharing.😀