Do Knife Grinders Damage Edges? Power Knife Sharpening And Bad Edges. Keith Nix Knives.

- Keith Nix

- May 23, 2023

- 6 min read

Updated: Oct 1, 2023

Let's Explore How To Prevent It Happening

WHAT'S UP WITH FACTORY EDGES?

Knife enthusiasts know that most factory knife edges are not as sharp and durable as those created by a skilled sharpener. Therefore, many knife owners prefer to sharpen their new knives immediately, with some suggesting that multiple sharpenings are needed to assess a factory knife's performance accurately. But why is this necessary? And do power grinders damage knife edges?

The BESS sharpness scale addresses this factory "dullness," noting that typical NEW high-end kitchen cutlery tests out on the Edge On UP! sharpness tester at 250-350 grams of force to cut the calibrated test media, while a kitchen knife done by a proficient sharpener can easily be in the 150-175 gram range.

It is essential to remember that knives produced in factories may have uneven edges due to the grinding process. The process usually involves rapidly moving belt grinders or wheels and may sometimes be done by hand. This can lead to discrepancies in the edge angle of up to ten degrees in bevels between the two sides of the edge and seven degrees from the heel to the tip.

However, this information is not the primary focus of today's discussion. Instead, we will discuss the potential harm that may arise from power grinding the apex or edge of a knife. By understanding the risks involved, we can take steps to ensure that we are using our knives safely and efficiently.

HOW HEAT AFFECTS THE EDGE OF A FINE KNIFE

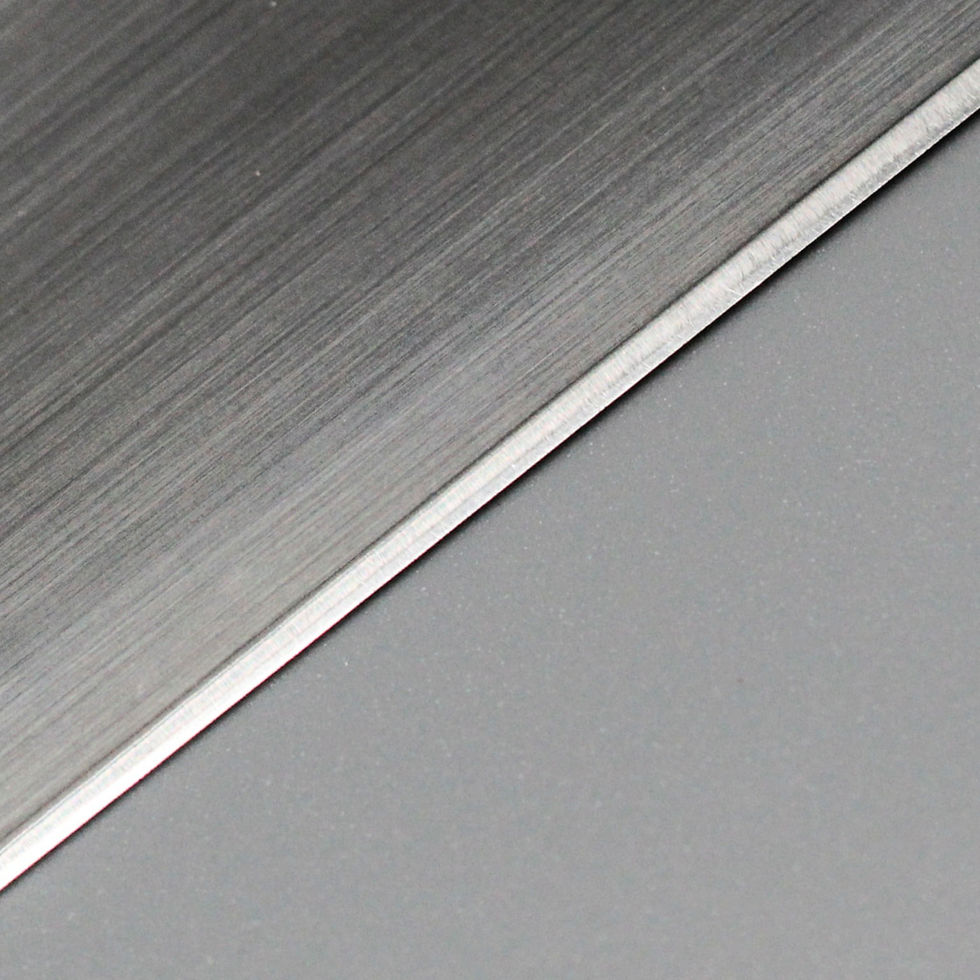

Grinding steel with abrasive wheels or a belt grinder generates heat due to the friction between the abrasives and the steel. The heat created during this process can be a genuine concern if it exceeds the original tempering temperature of the steel. If this happens, the knife's apex could become over-tempered, causing the steel to become softer. This can have a negative impact on the durability and performance of the knife.

The tempering temperature of the steel is a critical factor in determining its hardness and toughness. When the steel is heated to a specific temperature and then cooled, it undergoes a transformation that changes its properties. If the heat generated during grinding exceeds this temperature, it can undo the tempering process and cause the steel to become softer.

Furthermore, if the heat generated during grinding is allowed to continue increasing, it can cause the edge to re-harden and become untempered martensite again. This phase of steel is very hard but also very brittle. This can further compromise the overall quality of the knife by making the apex brittle and prone to chipping or breaking.

Therefore, it's crucial to approach knife grinding with great care and precision to ensure the best possible outcome. Remember that the apex of a knife is very thin, and heat build-up can be rapid and often catastrophic if not managed properly. Proper cooling and frequent checks of the temperature of the steel during grinding are essential to avoid over-tempering or re-hardening of the edge. By taking these precautions, you can ensure that your knife will maintain its durability and performance for a long time.

When grinding the blade of a knife, a moderate amount of heat is acceptable in the thicker regions, like toward the spine. This is because the steel volume of the blade functions as a heat sink and assists in the distribution of heat before higher temperatures can damage the blade. However, the scenario is different for the microscopically thin edge of the blade. A well-honed kitchen knife generally has an edge width of a half micron or less. (A micron is about .00004") This size is so minute that it can only be observed clearly with a scanning electron microscope. This minuscule area is of utmost importance and is highly susceptible to damage caused by heat. It is, after all, the BUSINESS part of the knife. Do power grinders harm knife edges? Making knives requires the steel to be heated to high temperatures, quenched quickly, or cooled down to room temperature, and then tempered at a lower temperature to reduce internal stresses. The typical tempering temperature is around 400°F (200°C ) or less. If a knife being sharpened is heated to a temperature lower than that tempering threshold, it's unlikely to cause any damage at all. However, the temperature can easily exceed that limit in the sub-micron area of the edge's apex within a second or less, resulting in a compromised "heat-affected zone." In this zone, grain structure, hardness, and temper will likely be affected. Edge stability and edge retention will be adversely affected. The heat-affected zone (HAZ) is an area of the knife edge that has not been melted but has undergone changes in properties due to exposure to relatively high temperatures. The HAZ is located from the apex back through the blade to the unaffected base material. This HAZ may be only a couple of thousandths of an inch back from the apex, but if it is there, your edge is degraded. Tempering color or "heat tint" is a useless barometer for checking for HAZ. If you're grinding fast and dry, HAZ cannot be avoided. Your knife won't hold an edge as well as it SHOULD. So, is it best to avoid the situation altogether? I believe it is, and there are ways to mitigate the creation of this heat-affected zone (HAZ). Let's go over a few:

1) Only Hand Sharpen Knives-- This isn't a viable option for professional knife makers and sharpeners. Still, it could be the answer for the home sharpener who only wants to keep personal knives keen and ready. Hand-sharpened edges haven't been exposed to the potential heat caused by grinding with belts or wheels.

2) Grind wet-- Add some water or a Kool Mist to your setup. It's messy, but it saves edges! Some sharpening machines come ready for wet grinding as well. Make sure your abrasive belts are the "wet/dry" variety. A belt not rated for wet use will disintegrate rapidly.

3) Grind Slowly-- Slow down the speed of your machine. A powered knife grinder, whether using belts or wheels, should be a variable-speed grinder. Does your machine have only one speed? Then don't grind knives on it. You cannot control the heat. If you're ruining your customers' knives or even your own, why are you doing that? Light pressure and quick passes can't stop the edge, the APEX, from being overheated.

4) Use Structured Abrasives-- Structured abrasive belts such as 3M Trizact generate far less heat than other types of belts while still moving material at an acceptable rate.

5) Dip The Blade-- Dipping the blade in cold water after each pass on your grinder will help prevent the build-up of excessive heat, but it WILL NOT save the apex of the edge. That heat and over-tempering does happen in milliseconds.

6) Hand Sharpen After Belt Grinding-- I do this for every knife I sharpen. ALL knives get sharpened by hand after a touch-up, edge thinning, or reprofile on the belt sander. This helps remove the possibility of HAZ. At Keith Nix Knives, we use all the other precautions when belt sharpening, thinning edges, or repairing chips, cracks, or broken tips. Then, as an added precaution, all finish work, or the final sharpening, is done by hand. Hand sharpening knives ensures we deliver the finest edges while minimizing the chance for a HAZ (heat-affected zone) that may ruin your blades.

SUMMARY: The Question is: DO KNIFE GRINDERS DAMAGE EDGES? The extremely small volume of material at the apex of a knife can be easily overheated to the point of overtempering. The knife sharpener needs to realize this and plan for it.

It is common for knife edges to overheat during power sharpening operations, as the small volume of steel at the blade's apex makes it prone to this issue. To minimize the chance of overheating, it is advisable to grind wet, grind slowly, use structured abrasives, and dip the blade in water. Hand sharpening ONLY is an effective way to eliminate or minimize this issue. Hand sharpening a small micro-bevel after grinding can also help. Exercising great care while sharpening a fine knife is essential, as it can be ruined in mere seconds if not appropriately handled.

As always, I'm grateful to the Knife Steel Nerd in charge, Dr. Larrin Thomas. I reference his article and study for much of this. If this subject interests you, I suggest you read Dr. Thomas' article. It can be found here: "Does Sharpening With A Grinder Ruin Your Edge?"

-By Dr. Larrin Thomas

Other sharpening posts and articles at Keith Nix Knives: Local Knife Sharpening in Black Mountain

828-337-7836

Thanks for reading,

Keith

Comments